pillars

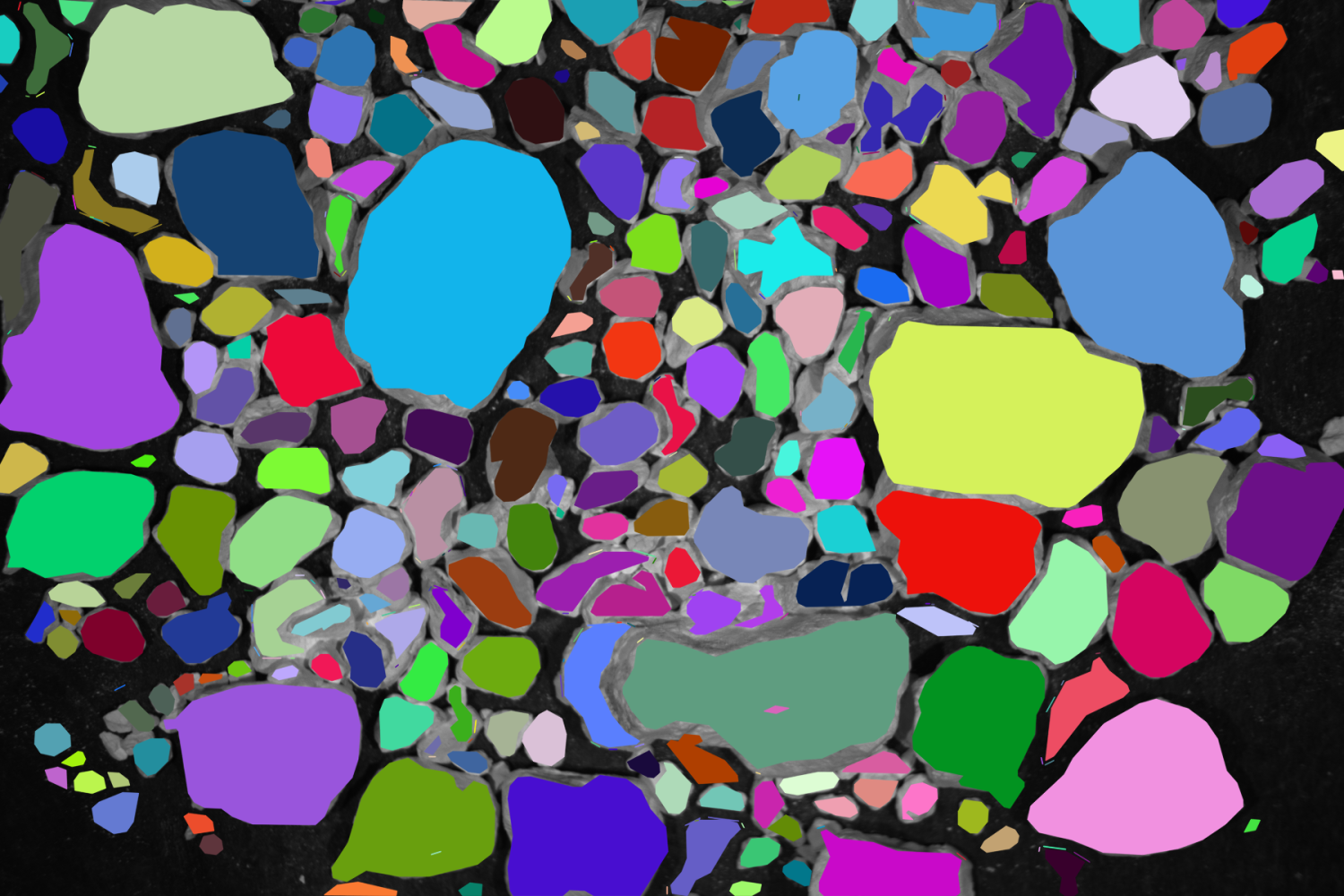

Object recognition

Real-Time Measurement

Production Monitoring

Real-time monitoring is essential for many industries, such as the food, mining, and construction sectors. Accurate measurement of particle sizes is crucial to ensure product quality and production process efficiency.

Thanks to artificial intelligence-based technology, it is now possible to conduct industrial production monitoring quickly, accurately, and efficiently. This technology combines the use of advanced sensors, intelligent algorithms, and real-time data analysis to provide instant and reliable results.

What are the advantages of using this technology?

First and foremost, real-time artificial intelligence-based technology offers continuous and uninterrupted monitoring of industrial production. This means you can obtain detailed information on particle sizes at the exact moment they occur, allowing for a swift response and correction if necessary. This timeliness is crucial for ensuring product quality and reducing waste.

Secondly, thanks to real-time artificial intelligence-based technology, you can automate the production monitoring process. This reduces reliance on manual measurements, reducing human errors and improving overall accuracy. Furthermore, automation saves time and resources, freeing up personnel for other important tasks.

Another advantage is the ability to analyze data in real-time and gain in-depth insights into particle characteristics. This can help you better understand your production processes, identify potential issues, and make targeted improvements to increase efficiency and product quality.

Additionally, using artificial intelligence enables you to predict and prevent future problems. Through historical data analysis and machine learning, you can identify patterns and trends, anticipating potential variations in production and taking preventive actions to avoid quality issues or production downtime.

Real-time artificial intelligence technology allows you to generate reports and intuitive data visualizations. This makes it easy to monitor and analyze production information, providing a comprehensive overview of your production process performance.

Using real-time artificial intelligence-based technology for industrial production monitoring offers significant benefits, including continuous and accurate measurements, process automation, real-time data analysis, problem prevention, and the generation of intuitive reports

Choose our artificial intelligence-based solution to achieve accurate and reliable industrial production monitoring.